Research - (2022) Volume 12, Issue 9

Properties of humatic reagent as a dust binding substance

O. Gerasimchuk1, A. Skachkov2, V. Shchokin3*, O. Omelchenko4 and V. Ezhov5Abstract

The paper presents the results of research and industrial tests of the effectiveness of the use of reagents for dust binding of dusty surfaces on the example of dry surfaces of tailings storage facilities of PJSC “InGZK” and PJSC “PivnGZK”. In the course of the research under contract No. 1205 dated 30.12.2021 between the Research Institute of Mining and Ore and PJSC "PivnGZK" from January 2022 until August 2022 two series of research on the properties of 16 reagents available on the market of Ukraine, which can be used for dust binding of dusting surfaces, were conducted, and a rating of reagents was formed according to the following indicators: stability of the protective layer; dust emission intensity; strength of the protective layer (ultrasonic method); the thickness of the protective layer; surface water absorption.

According to the results of laboratory studies, the binding process of finely dispersed dust particles, which actively participate in the general process of dust cloud formation in the conditions of dust formation of dry surfaces of tailings storage facilities, was substantiated, and a general rating of reagents based on the effectiveness of their use was formed.

Keywords

Mining processing plant, Tailings storage facility, Humate reagent, Industrial ecology.

Introduction

Known methods and measures to reduce dust formation at tailings storage facilities of industrial enterprises have not yet solved the environmental problem of dustiness of industrial sites and adjacent territories, which is confirmed by the definition of the problem of dust suppression as one of the priorities for industrial enterprises in the city of Kryvyi Rih in accordance with the decisions of Scientific and Technical Environmental Council under the Department of ecology and natural resources of Dnipropetrovsk Regional State Administration (clause 1, Minutes of Meeting No. 2 dated 09.06.2020), decisions of the Environmental Planning Council under the Department of ecology of the Executive Committee of Kryvyi Rih City Council (clause 4.1 of the Minutes of Meeting dated 27.10.2017, part II of the Minutes of Meeting dated 30.06.2018) regarding the implementation of measures of the City Program for solving environmental problems of Kryvbas and improving the state of the natural environment for 2016-2025, etc.

Materials and Methods

In the city of Kryvyi Rih, 93.4% of the total volume of industrial production is made up of the mining and metallurgical industry. At the same time, the intensive extraction of minerals in Kryvyi Rih, their processing and waste storage have led to the formation of anthropogenic relief, which causes constant pressure on the city's natural environment. Thus, the dynamics of dust emissions during 2018-2020 amounted to 34.90, 33.24 and 29.06 thousand tons, respectively.

One of the main unorganized sources of dust emissions are tailings of mining and beneficiation enterprises. With the wet tailings storage method, the hydromix of the tailings pulp is pumped into special hydrotechnical facilities-tailings storage facilities. The tailings, which are placed in the maps of the dam, on the slope areas quickly give off moisture, dry out and, at wind speeds of more than 3 m/s, subject to wind erosion, become the sources of dust emission into the atmosphere. The vast majority of tailings, by their fractional composition, belong to erosive and hazardous dust. The release of dust into the air from the dry surfaces of tailings storage facilities leads to the development of occupational lung diseases among workers of industrial enterprises and the deterioration of the general ecological situation in the area where the industrial object is located as a result of the release of pollutants into the air.

The amount of dust blown by the wind from the dry surfaces of the tailings storage maps mainly depends on the following main factors: wind speed, surface layer moisture and its fractional composition. The most unfavourable climatic factors occur in the warm summer period, when dry and hot weather, strong winds and a large deficit of air and soil moisture are recorded (V.A. Mykhaylov, et al., 1981; P.V. Beresnevych, et al., 1990).

In order to solve the problem of dust emission into the atmosphere from the dry surfaces of tailings on the basis of the Research Mining Institute of Kryvyi Rih National University, on the order of PJSC "PivnGZK", laboratory studies of binding dust-suppressing reagents were carried out, which fix the surface of the dust source due to the formation of a solid protective layer (crust). The effectiveness of providing the minimum period of protective coating, according to the technical task, is three months.

Results

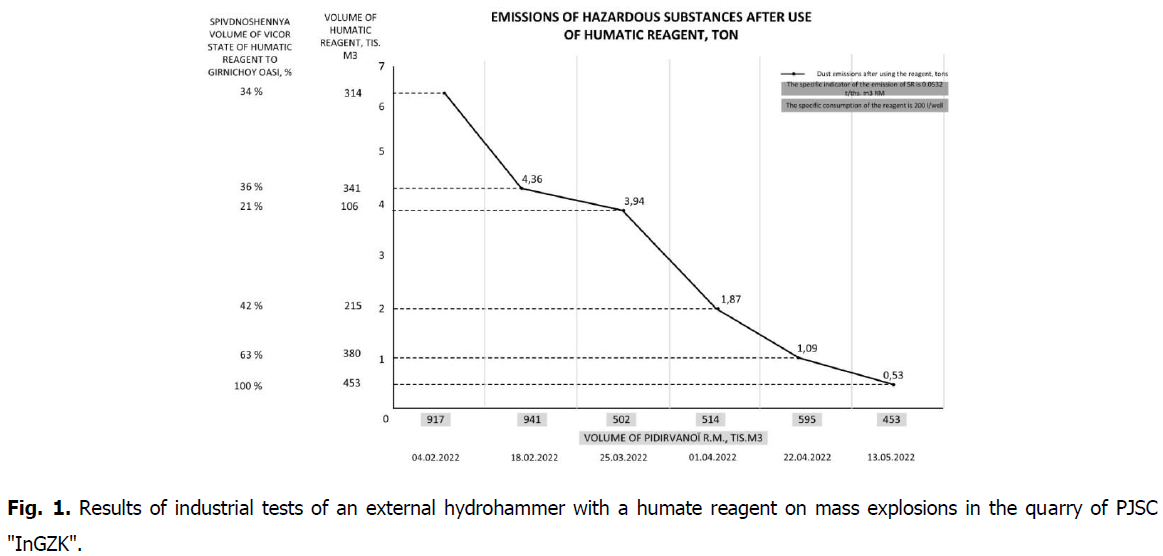

In order to theoretically substantiate the expediency of using selected reagents for dust suppression on the surfaces of tailings, a study of industrial adsorbents was conducted, where the main ones are activated carbon and its modifications. The use of a humate reagent, which production is carried out in accordance with V.P. Shchokin, 2020, in the composition of a working mixture as a filler for the sleeves of the external hydraulic hammer during mass explosions in the quarry of PJSC "InGZK" showed its ability to sorb gases and dust (Fig. 1).

Fig 1: Results of industrial tests of an external hydrohammer with a humate reagent on mass explosions in the quarry of PJSC "InGZK".

The humate reagent is a product, including the processing of lignite, the main active ingredients are sodium and potassium salts of humic acids and gelatinous substances, which are finely dispersed carbon-humic complexes. Common to humic acids of various origins is the presence of an aromatic core and peripheral open chains consisting of carboxyl, carbonyl groups, hydroxyls of an alcoholic and phenolic nature, and residues of nitrogen-containing amino acids. This structure of humic acids explains their adsorption properties. It is inserted that the process of adsorption of carbon monoxide (ll) of the carbon-alkaline reagent, which is a component of the humate reagent, is an exothermic process and has a significant value of ΔН. It is equal to-179 kJ/mol, which allows to conclude about the presence of chemisorption (not only physical, but also chemical sorption). The ability to sorb may be explained by the structure of the CO molecule, which is extremely stable, but which has an atom of an element that is able to participate in the formation of a covalent bond by the donor-acceptor mechanism. The electron donor is the oxygen atom. The sorption of nitrogen oxides and ammonia is possible by a similar mechanism. In the case of ammonia, the donor is nitrogen.

Effective neutralizers of carbon monoxide are potassium permanganate KMnO4 and hydrogen peroxide H2O2, which oxidize CO carbon monoxide to CO2 dioxide. It was proved by employees of the Research Mining Institute and Research Institute of Mining and Ore (Shchokin V., 2021; Gerasimchuk O., et al., 2021; Shchokin V., 2015) that physical sorption of gases occurs on activated carbon, while its ability to absorb carbon monoxide and nitrogen oxides, regardless of their chemical nature, and to form a stable protective layer (crust) from fine dust particles upon evaporation of moisture was experimentally confirmed.

Taking into account these circumstances, the following reagents were chosen as reagents for fixing the surfaces of tailings storage facilities: Humate reagent (aqueous solution 30%); Bischofite; Lexol-5; Enviro Binder ("Enviro Binder/water" ratio-1:39); Enviro Binder (Enviro Binder/water ratio-1:19); Freko Crust S (ratio "Freko Crust S/water"-1:12.33); Freko Crust S ("Freko Crust S/water" ratio-1:9); Freko Crust S ("Freko Crust S/water" ratio-1:7); Soil Loc (Soil Loc/water ratio-1:499); Soil Loc (Soil Loc/water ratio-1:199); Altprof brand A (ratio "Altprof brand A/water"-1:10.1); Altprof brand B (ratio "Altprof brand B/water"-1:10.1); Altprof brand B (the ratio "Altprof brand B/water" is 1:10.1); Liquid organic fertilizers; Sofir brand A (5% aqueous solution); Sofir brand B (5% aqueous solution).

Experiment planning

For the possibility of evaluating samples of dust-suppressing reagents, experimental sections (wooden formwork measuring 1250*1250*50 mm) were made, with the waste inside from the magnetite ore enrichment process, collected at the tailings repository of PJSC "PivnGZK". In order to create conditions close to real ones, the plot was located on the roof of the building of the Research Mining Institute of Kryvyi Rih National University. The tails in the experimental areas were coated with dust suppression reagents according to their application recommendations provided by their suppliers and manufacturers.

Research of the properties of the protective layer was carried out according to the cyclogram (Table 1).

| S.No. | Name of the reagent | March | April | May | June | July |

|---|---|---|---|---|---|---|

| 1 | Bischofite | ►Ⅰ | ►Ⅰ | |||

| 2 | Lexol-5 | ►Ⅰ | ►Ⅰ | |||

| 3 | Enviro Binder (1:39) | ►Ⅰ | ►Ⅰ | |||

| 4 | Enviro Binder (1:19) | |||||

| 5 | Freko Crust S (1:12.33) | ►Ⅰ | ►Ⅰ | |||

| 6 | Freko Crust S (1:9) | |||||

| 7 | Freko Crust S (1:7) | |||||

| 8 | Soil Loc (1:499) | ►Ⅰ | ►Ⅰ | |||

| 9 | Soil Loc (1:199) | |||||

| 10 | Altprof brand A (1:10.1) | ►Ⅰ | ►Ⅰ | |||

| 11 | Altprof brand B (1:10.1) | ►Ⅰ | ►Ⅰ | |||

| 12 | Altprof brand B (1:10.1) | ►Ⅰ | ►Ⅰ | |||

| 13 | Humate reagent (aqueous solution 30%) | ►Ⅰ | ►Ⅰ | |||

| 14 | Liquid organic fertilizers | ►Ⅰ | ►Ⅰ | |||

| 15 | Sofir brand A (5% aqueous solution) | ►Ⅰ | ||||

| 16 | Sofir brand B (5% aqueous solution) | ►Ⅰ |

Table 1. Cyclogram of experiments on reagents on surfaces (experiments to determine stability-marker ►Ⅰ).

Study of the stability of the protective layer

To determine the stability of the protective layer created by the reagents on the dusting surfaces, an external mechanical impact was applied. The factors of the criterion of resistance to mechanical influences are the mass of the ball, the height of the fall of the ball, the negative displacement of the impression and the contact area of the impression. The negative displacement of the impression is calculated by the formula:

where D-Is the diameter of the ball, mm;

d-diameter of the impression, mm.

The contact area of the impression is calculated according to the formula:

(2)

(2)

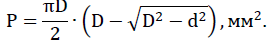

The maximum resistance to mechanical impact with the parameters h=const at d=0.8D is taken as the reference criterion for the stability of the crust. The results of studies of the stability of the protective layer of the first stage of research (resistance of reagents on the surface) are shown in Fig. 2.

Fig 2: Results of the first stage of research to determine the stability of the protective layer.

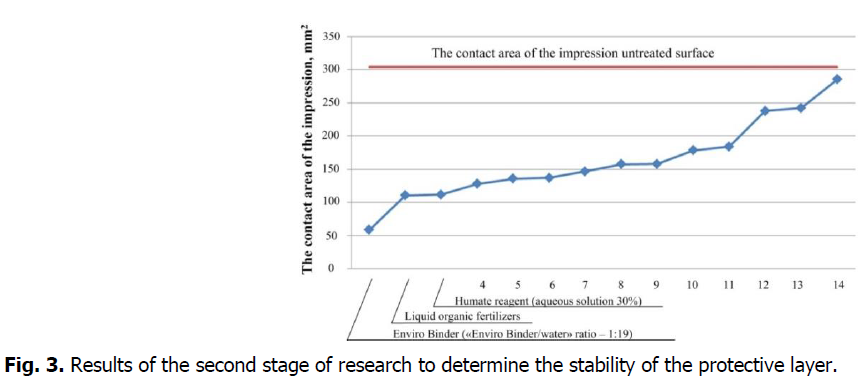

Since the right owner of the results obtained during the research is the customer, namely PJSC "PivnGZK", the names of the reagents are not displayed in Fig. 3, except for the reagents that, according to the sum of the results of all the studies, showed results 1-3. The above set will refer to the display of the results of all studies.

Fig 3: Results of the second stage of research to determine the stability of the protective layer.

Study of dust emission from tail surfaces

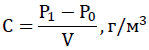

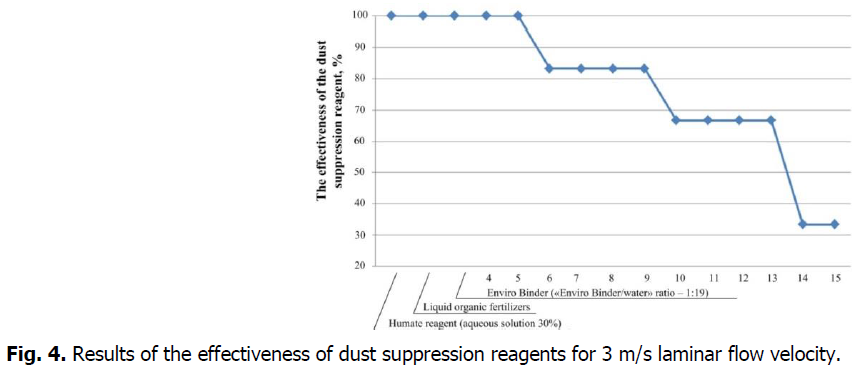

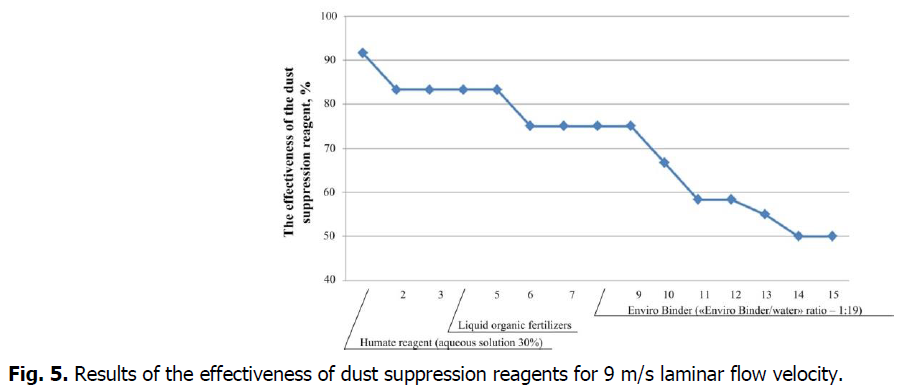

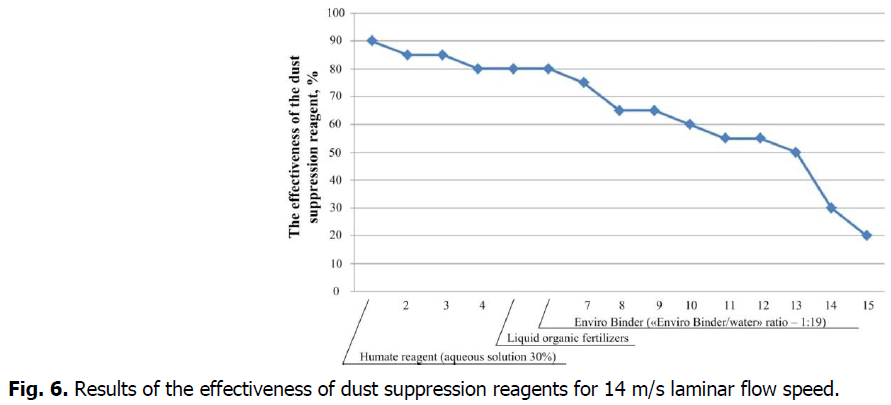

The dust concentration was determined by the formula (Fig. 4-6):

(3)

(3)

Where P0-is the weight of the filter after sampling, g;

P1– weight of the filter before sampling, g;

V-volume of air drawn through the filter, m3.

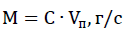

The intensity of dust emission from the dusting surfaces of tailings storage facilities is determined by the formula:

(4)

(4)

Where Vp-is the volumetric flow rate, m3/s.

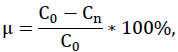

To determine the effectiveness of the dust suppression reagent (Mykhaylov, V.A., 1981), the concentration of dust rising from an untreated surface (taken as a base value) is determined and compared with the concentration of dust rising from a surface treated with the reagent (under the same input conditions) using the formula:

(5)

(5)

Where Co-is the concentration of dust rising from the untreated surface;

Cn-the concentration of dust rising from the surface treated with the reagent.

Fig 4: Results of the effectiveness of dust suppression reagents for 3 m/s laminar flow velocity.

Fig 5: Results of the effectiveness of dust suppression reagents for 9 m/s laminar flow velocity.

Fig 6: Results of the effectiveness of dust suppression reagents for 14 m/s laminar flow speed.

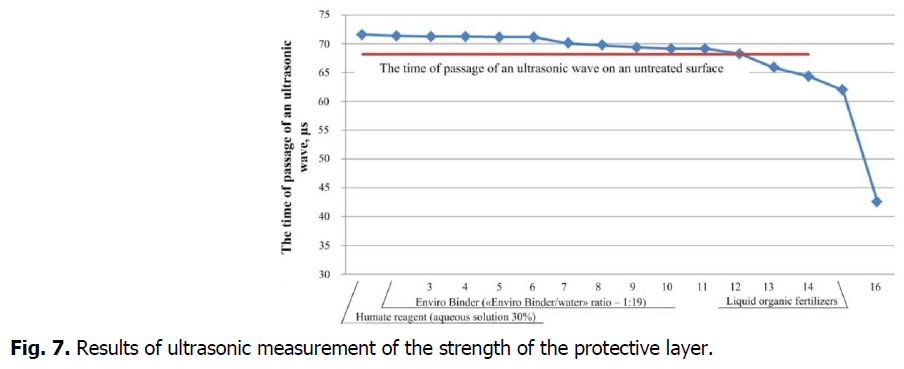

Study of the strength of the protective layer using ultrasonic waves

The ultrasonic device "UK-39" was used during the research. The device is designed to measure the time and speed of propagation of longitudinal ultrasonic waves in solid materials with through-sounding on an arbitrary base and surface sounding on a fixed base in order to determine the strength and integrity of materials. Such estimates are based on the correlation of the speed of propagation of ultrasonic waves in the material with its physical and mechanical characteristics and physical state. By measuring the speed of passage of ultrasonic vibrations, it is possible to obtain information about strength, porosity and homogeneity.

The research used a surface method of locating ultrasonic sensors. The distance between sensors in all areas was 50 mm. The basic result of measurements, and accordingly the minimum value of the time of passage of an ultrasonic wave, is 68.2 μs, which was obtained on an untreated surface (Fig. 7).

Fig 7: Results of ultrasonic measurement of the strength of the protective layer.

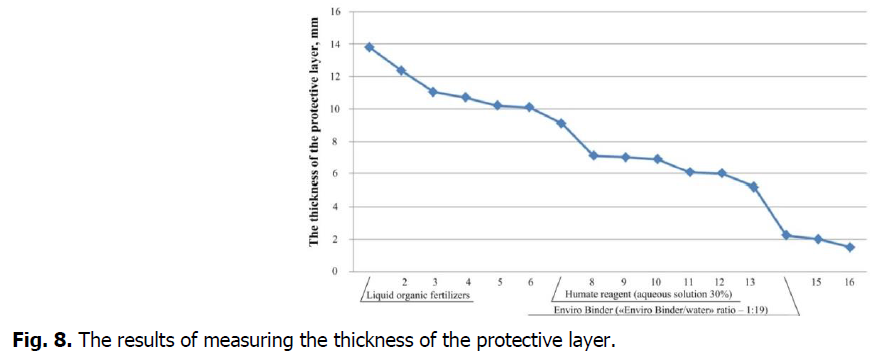

Measurement of the thickness of the protective layer (Fig. 8)

Fig 8: The results of measuring the thickness of the protective layer.

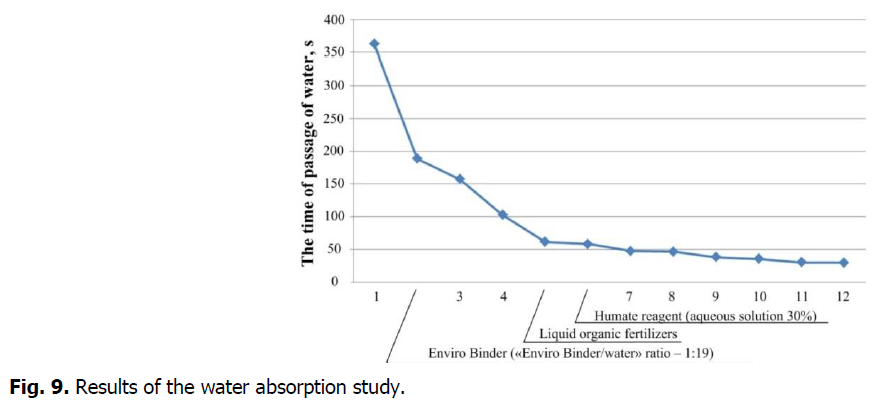

Study of water absorption

To conduct a study on water absorption, waste from the magnetite ore enrichment process was placed in a glass container and treated with reagents in accordance with the method of their application. The amount of water spilled on the surface was 250 ml. In this study, reagents 3, 5, 7 and 8 positions, respectively, according to Table 1, did not participate. Fig. 9 shows the obtained results of water absorption.

Fig 9: Results of the water absorption study.

Conclusion

In order to determine the special properties of reagents for fixing the surfaces of tailings storage facilities, the following indicators are proposed: stability of the protective layer; dust emission intensity; strength of the protective layer (ultrasonic method); the thickness of the protective layer; water absorption of the surface.

According to the conducted studies and taking into account the comprehensive efficiency indicator, the best properties are determined for the reagents: Liquid organic fertilizers; Humate reagent (aqueous solution 30%); Enviro Binder (Enviro Binder/water ratio-1:19).

The paper proves the working hypothesis regarding the formation of a stable protective layer of finely dispersed dust on the surfaces of tailings reservoirs due to the presence of finely dispersed carbon-humic complexes with the humate reagent.

References

Mykhaylov, V.A., Beresnevych, P.V., Borysov, V.G. (1981). Fighting dust in ore quarries. M.: Nedra, p:262.

Beresnevych, P.V., Mykhaylov, V.A., Filatov, S.S. (1990). Aerology of pits: Directory. M.: Nedra, p:280.

Shchokin, V.P., Yezhov, V.V., Kryvenko, O.Yu., Shchokina, O.V. (2020). Reagent composition for dust and gas suppression during mass explosions.

Shchokin, V., Ezhov, V., Shchokina, O., Chasova, E. (2021). Degasification and removal of dust at mass explosions in pits using a humate reagent in the internal and external storage. Ukrainian Journal of Ecology, 11:132-138.

Gerasimchuk, O., Shchokin, V., Zamriy, S., Ezhov, V. (2021). Degasation and dust control methods in major blasts in the open pit of inguletsky ore mining and processing complex (INGOK). research and industrial tests results. Ukrainian Journal of Ecology, 11:99-105.

Shchokin, V., Shchokina, O. (2015). Neuro-fuzzy activation sub-system of effective control channels in adaptive control system of agglomerative process. Metallurgical and Mining Industry, 3:6-14.

Shchokin, V., Shchokina, O. (2015). Theoretical foundations of extension of ARMA (AutoRegressive with Moving Average) model with the usage of connectionist technologies (Brain-inspired Systems). Metallurgical and Mining Industry, 2:11-18.

Author Info

O. Gerasimchuk1, A. Skachkov2, V. Shchokin3*, O. Omelchenko4 and V. Ezhov52CEO of PJSC PJSC, Northern Ore Mining and Processing Plant, ul. Rudna, 47 Krivoy Rog, 50064, Ukraine

3Director Research Mining Institute of the Krivoy Rog National University, Gagarin Avenue, 57. Krivoy Rog, 50086, Ukraine

4Department of General Engineering Disciplines, Equipment of Mykhailo Tuhan-Baranovskyi Donetsk National University of Economics and Tradeul. Rudna, Krivoy Rog, 50064, Ukraine

5Research Institute of Labor Safety and Ecology in the Mining, Metallurgical Industry of the Krivoy Rog National University, Pershotravneva str.12, Krivyi Rih, 50000, Ukraine

Citation: Gerasimchuk, O., Skachkov, A., Shchokin, V., Omelchenko, O., Ezhov, V. (2022). Properties of humatic reagent as a dust binding substance. Ukrainian Journal of Ecology. 12:30-37.

Received: 04-Oct-2022, Manuscript No. UJE-22-76509; , Pre QC No. P-76509; Editor assigned: 06-Oct-2022, Pre QC No. P-76509; Reviewed: 17-Oct-2022, QC No. Q-76509; Revised: 22-Oct-2022, Manuscript No. R-76509; Published: 27-Oct-2022, DOI: 10.15421/2022_401

Copyright: This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.